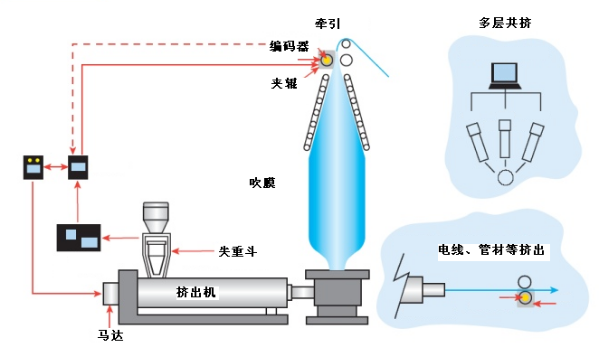

The extrusion control system is used to facilitate the adjustment of the process and the interlayer ratio, which reduces the startup time and specification change time and reduces the amount of waste.

In product thickness control, since the extrusion control system can control production more evenly, lower deviations can be adopted to produce and save raw materials.

Extrusion control system, the total raw material saving is 3~5%.

Mateco Machinery

Mateco Machinery